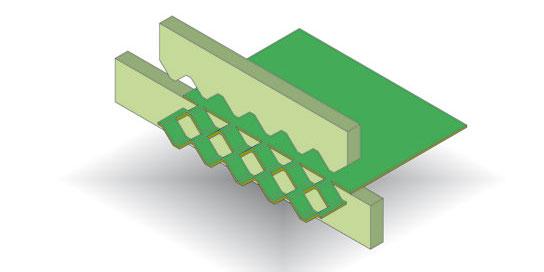

How expanded mesh is made

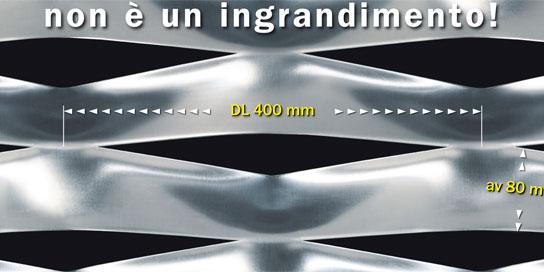

The shape of the blades used to cut the sheet metal determines the shape and size of the expanded mesh. The semi-finished product has a continuous, robust structure thanks to the absence of seams. The blades are tools machined from materials of elevated hardness, capable of making a clean cut even in metals up to 5 mm thick.